Technical articleThe solution to the temperature out of control of the constant temperature electric soldering iron

The constant temperature electric soldering iron adopts high Curie temperature strip-shaped PTC constant temperature heating element inside, and is equipped with a fastening heat conduction structure. The characteristic is that it is superior to the traditional heating wire soldering iron core, with rapid heating, energy saving, reliable operation, long life and low cost. It can be used in the field with a low-voltage PTC heating core, which is convenient for maintenance work.

The solution to the temperature out of control of the constant temperature electric soldering iron

A common failure with thermostatic soldering irons is temperature runaway, which results in overheating of the soldering iron. On the one hand, it leads to high-temperature oxidation of the soldering iron tip (solder is also oxidized at the same time); on the other hand, soldering at high temperature is also easy to burn out electronic components. When the electric soldering iron works at high temperature for a long time, it is also easy to cause damage to its internal circuit, resulting in permanent loss of control or even inability to use it. During the fault inspection, it will be found that the sliding contact of the temperature adjustment resistor R2 (Figure 1) is oxidized and has poor contact, which is equivalent to the temperature being adjusted to the maximum upper limit, so the temperature of the soldering iron is too high. There are two fundamental reasons: one is that when the electric soldering iron is working, a part of heat is transferred to the handle of the soldering iron (built-in circuit), which increases the temperature of the circuit working environment. After a period of time, it is easy to cause the movable contact of R2 to oxidize; the second is that the current-limiting resistor R1 (Figure 2) in the rectifier filter circuit dissipates and dissipates heat, which causes the temperature of the working environment of the circuit to rise and easily causes the movable contact of R2 to oxidize.

In order to prevent the occurrence of this kind of failure, the following two methods of modifying the circuit are proposed for reference.

(1) Replace the adjustable resistor R2 with a fixed resistor: first adjust R2 to make the temperature of the soldering iron reach the optimum temperature point for normal use, then measure the value of R2 and replace it with a fixed resistor.

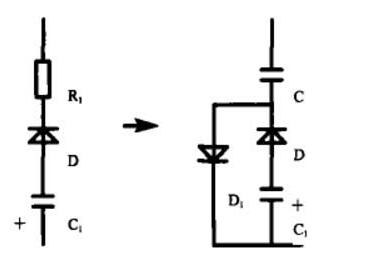

(2) Transformation of the rectifier circuit: the circuit structure is shown in Figure 3.

Replace R1 with C (C≈0.12μF), and connect a diode D1 in parallel.